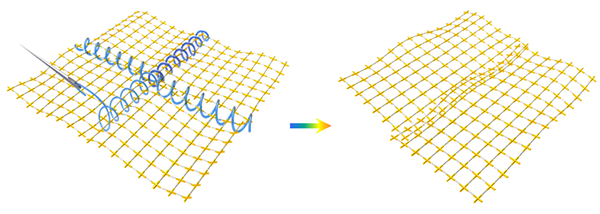

Figure. Schematic diagram for the formation of interwoven grain boundary

Supported by the National Natural Science Foundation of China (Grant No. 52061135103 and 51873236), Prof. Zhikun Zheng from Sun Yat-sen University and Guangdong University of Technology, along with his coworkers, has reported a breakthrough in the development of highly crystalline, yet tough and elastic, organic polymer membranes. The related research was titled “Elastic films of single-crystal two-dimensional covalent organic frameworks” and published in Nature on June 27, 2024.

The link to the paper is: http://www.nature.com/articles/s41586-024-07505-x.

Naturally occurring and synthetic materials are often polycrystalline and typically, higher crystallinity results in increased brittleness. This creates a trade-off between mechanical stability, essential for practical applications, and the long-range crystal order affected by grain boundaries, which can dominate the properties of material. Like other materials, crystalline substances also experience trade-offs between mechanical rigidity and toughness. However, crystals are often processed into macroscopic films, which are inherently polycrystalline and contain numerous grain boundaries. As a result, achieving highly crystalline membranes with enhanced mechanical rigidity and toughness remains a significant challenge.

Given that products can enhance mechanical rigidity and toughness through interweaving of their components, common in amorphous polymers, the research team introduced sacrificial amorphous polymer components. These components served as “shuttles”, facilitating the interweaving of adjacent single-crystal domains within the crystalline polymer membranes, resulting in interwoven grain boundary structures. The obtained membranes use a fully crystalline structure to provide mechanical rigidity and energy dissipation offered by the sliding of the interwoven structure at the grain boundaries to enhance mechanical toughness. The obtained membranes showed Young’s moduli similar to that of aluminum alloy, while their fracture strength and elongation at break exceeded those of aluminum alloy, while their fracture strength and elongation at break surpassed those of aluminum. When subjected to external impact, fractures were confined to the force concentration points. In contrast, once cracks were formed, they rapidly propagated, adversely affecting the mechanical properties of other highly crystalline materials. In addition, the membranes displayed resistance to rubbing, a property that is often difficult to achieve in other highly crystalline materials.

This work establishes a foundation for the use of fully crystalline materials in flexible devices and separation membranes. Flexible crystalline materials can be used to produce various applications, including flexible chips, displays, batteries, and sensors. Membrane-based separation technology is widely employed in fields such as chemical engineering, environmental protection, energy, and biotechnology. Compared to conventional separation membranes, fully crystalline polymer membranes are expected to achieve higher purity substances with greater efficiency due to their superior regularity. This is especially beneficial in high-value-added sectors where traditional separation membranes face challenges, such as the precise separation of chemical intermediates and the purification of high-purity electronic chemicals and pharmaceutical intermediates.

Add: 83 Shuangqing Rd., Haidian District, Beijing, China

Postcode: 100085

Tel: 86-10-62327001

Fax: 86-10-62327004

E-mail: bic@donnasnhdiary.org

京ICP备05002826号 文保网安备1101080035号 Copyright 2017 NSFC, All Right Reserved